Dip in Unit Labor Costs Signals Compromised Workers

Look around you. What do you see on your desk? Chances are, you have some item that was made here in the United States. The work that went into getting that product to you is, of course, intense, and the site of great compromise for workers and employers alike.

As a recruiter, you know how much negotiation goes into calculating the benefits and salary for each worker.

When it comes to manufacturing, these negotiations culminate in “unit labor costs.” These costs are determined largely by workers’ financial compensation. These figures measure the productivity calculated by dividing total labor compensation (including benefits) by real output.

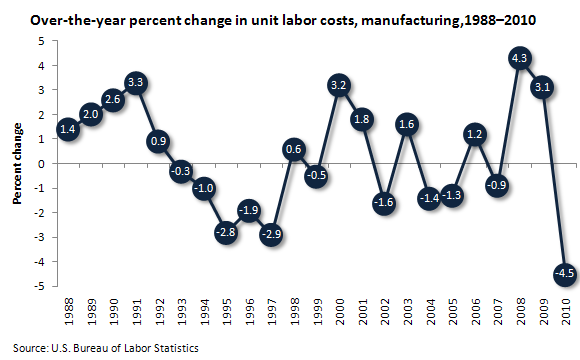

According to the Bureau of Labor Statistics, from 2009 to 2010, unit labor costs in the manufacturing sector fell 4.5 percent—the largest decline since the series began in 1988.

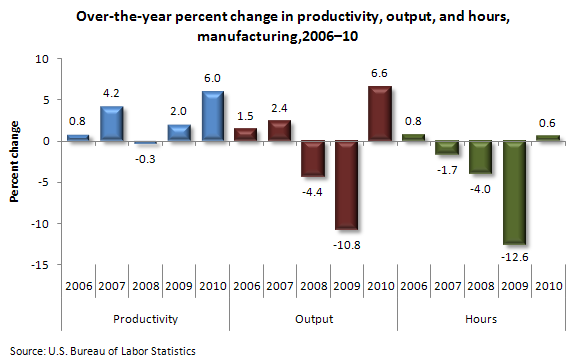

Over the year, labor productivity—defined as output per hour—grew 6.0 percent in 2010. This increase was the largest annual increase in output per hour since 2003, when output per hour increased 6.3 percent. The productivity gain reflected a 6.6-percent increase in output combined with a 0.6-percent increase in hours.

From 2009 to 2010, productivity grew 8.2 percent in durable goods manufacturing and 3.5 percent in nondurable goods industries.

On the one hand, these figures suggest a prosperous nation in which there are signs of an economy on the mend; however, what sacrifices are being made to keep the costs so low? Does this change suggest that people are not being paid fairly and equitably?